Sustainable practices in PCB fabrication have become increasingly critical in today’s electronics industry as companies strive to reduce their environmental impact and embrace eco-friendly manufacturing processes. In this article, we delve into the realm of sustainable PCB fabrication, focusing on the efforts of PCB-Togo Electronic, Inc. as a leading example of environmental responsibility in the field. From analyzing the traditional environmental footprint of PCB fabrication processes to exploring innovative strategies for minimizing impact, this article highlights the significance of sustainability in electronics manufacturing and the benefits it offers for both the industry and the environment.

Overview of PCB Fabrication Process

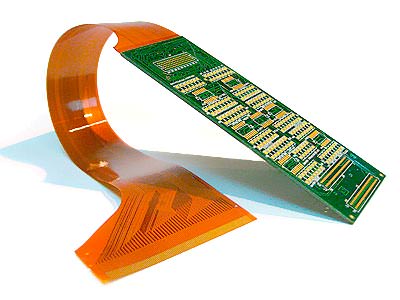

When it comes to making printed circuit boards (PCBs), it’s not just about slapping some components on a board and calling it a day. PCB fabrication involves intricate processes like etching, drilling, and soldering to bring your devices to life.

Importance of Sustainability in Electronics Manufacturing

With the rise of green initiatives and environmental consciousness, the spotlight is on sustainability in electronics manufacturing. The electronic industry’s impact on the environment is no joke, and adopting sustainable practices in PCB fabrication is crucial to reduce this impact.

PCB-Togo Electronic, Inc.: Leading the Way in Environmental Responsibility

Company Background and Mission

Enter PCB-Togo Electronic, Inc., a company on a mission to marry technology with environmental responsibility. This innovative company is not just about making circuits—it’s about doing so in a way that’s kind to our planet.

Commitment to Sustainable Practices

At PCB-Togo Electronic, Inc., sustainability isn’t just a buzzword—it’s a way of life. From their materials sourcing to manufacturing processes, every decision is made with the environment in mind. They’re setting the bar high for the electronics industry.

The Environmental Impact of Traditional PCB Fabrication Processes

Chemical Usage and Waste Generation

Traditional PCB fabrication processes can be pretty heavy on the chemicals, leading to significant waste generation. These chemicals can have harmful effects on both the environment and human health if not managed properly.

Energy Consumption and Carbon Emissions

Energy consumption in PCB fabrication can be sky-high, contributing to carbon emissions and environmental degradation. The carbon footprint of traditional processes is nothing to scoff at, making it clear why sustainable alternatives are needed.

Strategies for Reducing Environmental Impact in PCB Fabrication

Switching to Eco-Friendly Materials

One way to lessen the environmental impact of PCB fabrication is by switching to eco-friendly materials. From biodegradable substrates to lead-free solder, these alternatives can significantly reduce the ecological footprint of the manufacturing process.

Implementing Energy-Efficient Manufacturing Processes

Energy-efficient manufacturing processes are another key strategy to reduce environmental impact. By optimizing energy usage, minimizing waste, and employing green technologies, PCB fabrication can become more sustainable and less taxing on the planet.

Innovations in Sustainable Materials and Technologies

Overview of Sustainable PCB Materials

When it comes to sustainable PCB fabrication, using eco-friendly materials is all the rage. From biodegradable substrates to recycled copper, the world of PCBs is getting a green makeover. These materials not only reduce environmental impact but also pave the way for a more sustainable future.

Advancements in Green Manufacturing Technologies

Say goodbye to old-school manufacturing methods that harm the planet! With advancements in green manufacturing technologies like water-based inks and energy-efficient processes, PCB fabrication is getting a much-needed eco-friendly upgrade. It’s like giving Mother Earth a high-five.

Implementing Sustainable Practices at PCB-Togo Electronic, Inc.

Initiatives and Programs for Environmental Sustainability

At PCB-Togo Electronic, Inc., sustainability isn’t just a buzzword—it’s a way of life. Through initiatives like waste reduction programs and energy-efficient practices, they’re leading the charge in eco-conscious PCB fabrication. It’s like Captain Planet meets the tech world.

Successes and Challenges of Implementation

While PCB-Togo Electronic, Inc. is making waves in the sustainability game, it hasn’t been all smooth sailing. From overcoming resistance to change to navigating the complexities of sustainable sourcing, they’ve faced their fair share of challenges. But hey, nothing worth doing is ever easy, right?

Benefits of Sustainable PCB Fabrication for the Industry and Environment

Economic Advantages of Sustainability

Who says being sustainable can’t be profitable? Sustainable PCB fabrication isn’t just good for the planet—it’s good for business too. From cost savings through energy efficiency to attracting eco-conscious customers, going green is a win-win for everyone involved.

Positive Environmental Impacts and Long-Term Benefits

By choosing sustainable PCB fabrication, we’re not just reducing our carbon footprint—we’re making a positive impact on the environment for years to come. From preserving natural resources to minimizing waste, the long-term benefits of sustainability are like a gift that keeps on giving. Let’s keep the green vibes flowing, one PCB at a time.

In conclusion, the adoption of sustainable practices in PCB Fabrication Taiwan not only aligns with environmental stewardship but also presents tangible benefits for businesses and the planet alike. By championing eco-friendly materials, implementing energy-efficient processes, and fostering a culture of environmental responsibility, companies like PCB-Togo Electronic, Inc. are paving the way for a greener future in electronics manufacturing. As we continue to prioritize sustainability in every aspect of our operations, we can collectively contribute to a more sustainable and resilient industry for generations to come.