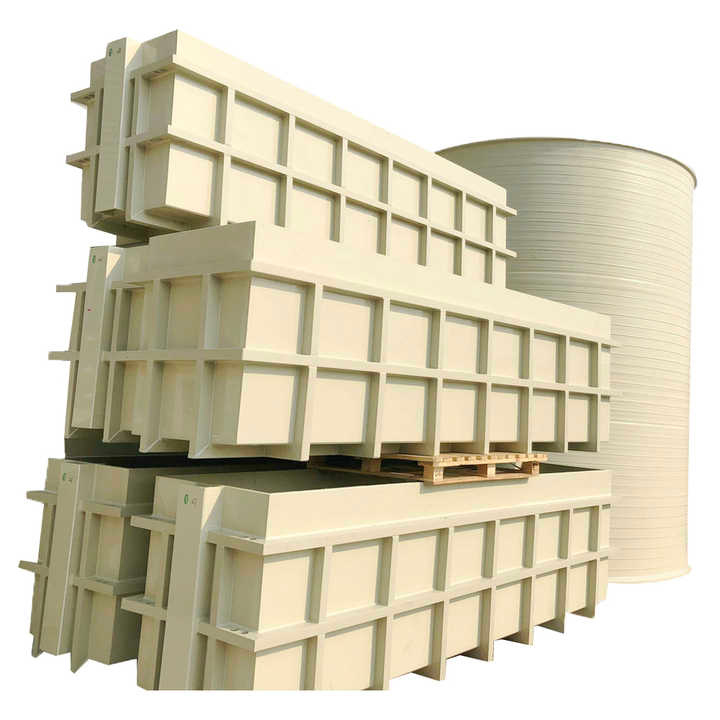

When it comes to chemical storage and handling, the choice of materials and manufacturing expertise can make all the difference. Polyvinylidene fluoride (PVDF) tanks are a game-changer in industries requiring high chemical resistance and durability. Petron Thermoplast is the best PVDF tank manufacturer specialize in crafting premium PVDF tanks designed to meet the rigorous demands of industrial applications.

Why PVDF Tanks?

PVDF is a high-performance thermoplastic known for its exceptional resistance to chemicals, UV radiation, and extreme temperatures. Its unique properties make it an ideal choice for industries handling corrosive substances and requiring reliable storage solutions. Key benefits of PVDF tanks include:

- Superior Chemical Resistance: Withstand acids, bases, and solvents without degradation.

- High Thermal Stability: Perform reliably across a wide temperature range.

- UV Resistance: Ideal for outdoor applications due to excellent weathering properties.

- Durability: Long service life, even under harsh industrial conditions.

- Low Maintenance: Minimal upkeep required due to its robust nature.

Applications of PVDF Tanks

PVDF tanks manufactured by Petron Thermoplast are used across a diverse range of industries. Some common applications include:

1. Chemical Processing

- Safe storage and transportation of highly corrosive chemicals.

- Utilized in reactors and mixing tanks for aggressive substances.

2. Water Treatment

- Effective containment of chlorine, acids, and other treatment chemicals.

- Resistance to UV makes them suitable for outdoor installations.

3. Pharmaceuticals

- Ideal for handling high-purity chemicals in pharmaceutical manufacturing.

- Compliance with hygiene and safety standards.

4. Electronics Manufacturing

- Storage of etching and cleaning solutions in semiconductor and electronics production.

5. Food and Beverage

- Suitable for food-grade chemical storage due to non-toxic properties.

- Resistance to cleaning agents and sterilization processes.

6. Renewable Energy

- Used in solar and battery industries for handling chemical components during production.

Why Choose Petron Thermoplast?

At Petron Thermoplast, we combine industry expertise, advanced manufacturing technologies, and a commitment to quality to deliver the best PVDF tank solutions. Here’s what sets us apart:

1. Customization to Your Needs

Every industry has unique requirements, and we offer fully customized PVDF tanks to meet specific operational demands, including:

- Size and capacity customization.

- Tailored fittings and accessories.

- Enhanced features for specific applications.

2. Precision Engineering

Our state-of-the-art fabrication techniques ensure that every tank meets the highest standards of precision and quality. With advanced welding and molding technologies, we guarantee leak-proof designs and robust performance.

3. Compliance with Industry Standards

We adhere to international safety and quality standards, ensuring our PVDF tanks are reliable and safe for industrial use.

4. Sustainable Manufacturing Practices

Petron Thermoplast is committed to environmentally friendly practices, using energy-efficient processes and recyclable materials where possible.

Industries We Serve

Petron Thermoplast PVDF tanks are trusted by leading companies in:

- Chemical and Petrochemical

- Pharmaceuticals

- Water and Wastewater Treatment

- Food and Beverage

- Electronics Manufacturing

- Renewable Energy

Sustainability and Innovation

As a forward-thinking manufacturer, we prioritize innovation and sustainability. Our PVDF tanks are designed to minimize environmental impact while maximizing efficiency and performance. By choosing Petron Thermoplast, you invest in a solution that supports long-term industrial growth and environmental responsibility.

Key Benefits of PVDF Pipes

1. Unmatched Chemical Resistance

PVDF pipes are highly resistant to a wide range of chemicals, including acids, alkalis, halogens, and organic solvents. This property makes them ideal for transporting aggressive substances in industries like chemical processing and wastewater treatment.

2. Thermal Stability

PVDF pipes maintain their structural integrity and performance across a broad temperature range, from -40°C to 150°C. This versatility allows their use in both cryogenic and high-temperature applications.

3. Superior Durability

These pipes offer excellent resistance to abrasion, UV radiation, and weathering, ensuring long-term reliability in demanding outdoor or industrial environments.

4. Low Permeability

PVDF pipes have low permeability to gases and liquids, reducing the risk of leaks or contamination in fluid handling systems.

5. Lightweight and Easy to Install

Despite their strength, PVDF pipes are lightweight, simplifying transportation and installation. This reduces labor costs and downtime during maintenance or upgrades.

6. Eco-Friendly and Safe

PVDF is a non-toxic material that does not release harmful by-products during manufacturing or use. It is also compliant with FDA and other regulatory standards for applications involving potable water and food processing.

Installation and Maintenance Tips for PVDF Pipes

To maximize the performance and lifespan of PVDF pipes, consider the following:

- Proper Handling: Avoid excessive bending or impact during transportation and installation.

- Correct Joining Techniques: Use heat fusion or appropriate fittings for secure and leak-proof connections.

- Routine Inspections: Periodically check for signs of wear, abrasion, or external damage.

- Compatibility Checks: Ensure the transported fluids are compatible with PVDF to avoid chemical degradation.

Partner with Petron Thermoplast

With years of expertise and a dedication to excellence, Petron Thermoplast is your trusted partner for PVDF tank manufacturing. Whether you need a standard design or a fully customized solution, our team is ready to deliver.

Contact us today to learn more about our PVDF tank solutions and how we can help meet your industrial storage needs. With Petron Thermoplast, you’re choosing quality, reliability, and innovation.